We've been using solar panels for over a decade now. To begin with, we

used them only to charge the UPS batteries that kept our work computers

running during power failures (outages of 6–8 hours were common). Over

time, we've expanded our generation and storage to support our entire

domestic load.

For the past two decades, no matter where we were, the two most

important factors for our work were reliable power and connectivity.

When we decided to move to a small village in Uttarakhand in 2013, we

knew it would take a lot of time, effort, and money to ensure that we

had a robust setup.

I say this right at the beginning in order to emphasise that the popular

idea of investing in solar power as an income-generation (or

"income-less-eating", at least) measure was laughably distant from our

situation. Not once did we ever try to calculate the break-even point

for our solar generation. For us, the only question was whether we

could work or not.

Mains power

The mains power supply is unreliable, to put it mildly.

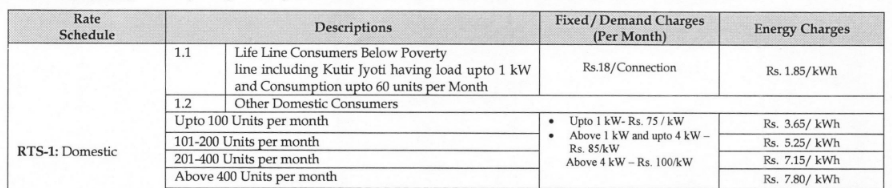

Uttarakhand Power Corporation Limited

(UPCL) is the only power distribution company in the state. We have a

domestic connection with a sanctioned load of 3kW. There's a

meter installed at our door, and the linesman, who lives in a

neighbouring village, collects the reading every month and generates a

bill, which we pay online. As of April 1, 2025, these are the

applicable tariffs.

Power outages are frequent, and can last for a few minutes or several

days. Being a small village, we're subject to load

shedding when demand elsewhere is high; and if a tree falls on a

power line, or a transformer blows up, it might take a week to restore

the supply.

Outages longer than a day or so may happen only once a year, or less if

we're lucky, but 6–12 hour power failures are much more frequent, and

not having power for a couple of hours is an almost daily occurrence.

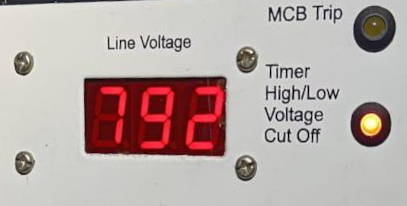

The mains power supply is also prone to wild, prolonged voltage

fluctuations, especially after a big outage. We've seen everything from

25V to 792V instead of the 230V it's supposed to be. This is incredibly

destructive, leaving us with a string of burned-out equipment (including

inverters, microwave ovens, and voltage stabilisers) and tens of

thousands in repair costs.

We eventually found and installed the

Accurex DPM-3000,

a voltage cut-off device that has reliably withstood these fluctuations

and kept all of the downstream equipment safe for years.

Our domestic load

Our house is wired such that everything can run off the inverter. It's

entirely up to us to avoid overloading the inverter (currently 5kVA) by

using the microwave (2.2kW) and dishwasher (2.4kW) together, for

example. We do have some plug points wired directly to the mains

supply, which we can use for things like the steam mop and vacuum

cleaner.

We have about 400W of computer equipment (computers, wifi routers,

etc.) and

a refrigerator and deep freezer

running all the time. We can bring that down to under 200W or so by

switching off some or all of the computers if we're running short of

battery power during a long outage.

We have a surprising number of appliances that consume between 1–2.5kW.

Kitchen equipment (e.g., dishwasher, convection oven, microwave oven)

has a higher priority than everything else (e.g., 2.2kW circular saw).

In good weather, we now have enough capacity to keep the batteries

charged while scheduling other loads in order to take advantage of

surplus generation. For example, we plan our cooking and baking so that

the oven and dishwasher run one after another in the middle of the day,

with a break in between to heat our lunch in the microwave.

Inverters, PCUs, and everything in between

We've used eight inverters over the past twelve years. We started with

1kVA (just the computers), upgraded to 2kVA, 3kVA, 4kVA, and are

currently at 5kVA (everything, but not all together).

We've used mains-only inverters with MPPT and non-MPPT solar chargers,

and integrated solar PCUs comprising an inverter, a grid charger, and an

MPPT or non-MPPT solar charger. (We have not used a grid-tied or hybrid

inverter, for reasons explained later.)

Our current setup

At the time of writing, we are using a

Statcon Energiaa

SEOG 5kVA/48V solar PCU, which is supposed to be one of the most

reliable systems for off-grid use in India. It's a massive fellow

with a heavy transformer inside.

The most interesting feature of this PCU is an operating mode that tries

to reduce mains power usage without discharging the batteries too much.

This mode lies somewhere between the standard SBG (Solar > Battery

> Grid) mode where the system avoids using grid power as much as

possible, and SGB mode where the system avoids discharging the

batteries.

Normally, with S>B>G priority, you would save on power costs, but

could be left without enough power stored in the batteries to survive a

long outage at night. On the other hand, with S>G>B, you would

spend a lot more on keeping the batteries topped-up even when there is

no outage. With this PCU, you can set a threshold battery voltage at

which it will begin to charge the batteries from the mains supply.

In practice, with our load management, the PCU will run everything off

solar during the daytime in good weather, switch to battery power

mid-afternoon, and switch back to mains power only the next

morning, when solar charging can recommence soon afterwards anyway.

(The trigger to switch to mains is usually me switching on the electric

kettle in the morning.) The effect is visible in our electricity bills.

Unfortunately, we had a lot of trouble with this PCU tripping randomly

(and later, massively overcharging the batteries). It took many phone

calls, three visits from a technician, a lot of head-scratching, three board changes, and

making a bit of a fuss when things dragged on for several months, but

the PCU seems to be working as expected now.

I wrote a script named

seog-status.py

to interpret the monitoring data from the PCU's serial port. Having this

data was invaluable in optimising our load management, and to keep an

eye on things when the PCU was misbehaving.

status=R/F/n/B, AC=(229.1V; 0.6A), BAT=(55.5V; 24.2A), PV=(140.6V; 14.1A; 1979W; 2.21kWh)

status=R/F/n/B, AC=(230.1V; 0.6A), BAT=(55.6V; 24.5A), PV=(141.1V; 14.1A; 1981W; 2.21kWh)

status=R/F/n/B, AC=(230.1V; 0.6A), BAT=(55.7V; 24.4A), PV=(139.7V; 14.2A; 1991W; 2.21kWh)

status=R/B/n/B, AC=( 0.0V; 0.0A), BAT=(55.8V; 32.0A), PV=(144.2V; 13.2A; 1917W; 2.21kWh)

status=R/B/n/B, AC=( 0.0V; 0.0A), BAT=(56.3V; 32.9A), PV=(139.3V; 14.3A; 2008W; 2.21kWh)

status=R/B/n/B, AC=( 0.0V; 0.0A), BAT=(56.4V; 32.9A), PV=(140.6V; 14.2A; 2010W; 2.21kWh)

status=R/B/n/B, AC=( 0.0V; 0.0A), BAT=(56.4V; 33.0A), PV=(140.9V; 14.2A; 1992W; 2.21kWh)

status=R/B/n/B, AC=( 0.0V; 0.0A), BAT=(56.4V; 32.9A), PV=(141.3V; 14.1A; 2010W; 2.21kWh)

status=R/F/n/B, AC=(228.5V; 0.6A), BAT=(55.9V; 24.7A), PV=(139.7V; 14.4A; 1982W; 2.44kWh)

status=R/F/n/B, AC=(230.6V; 0.6A), BAT=(55.7V; 24.8A), PV=(141.1V; 14.3A; 1997W; 2.44kWh)

Our backup system

As a backup system, we have a

5kVA/48V online UPS from Microtek

and a standalone MPPT charger, the

Neon 80 HV from Ashapower.

We've installed and tested them. They work pretty well together.

As far as I'm concerned, Microtek

simply makes the best UPSes (n=2). Their output voltage regulation is

excellent, and they have been generally trouble-free over many years.

Another point in their favour is that they have a service centre in

Haldwani. They claim to manufacture

an integrated 5kVA/48V MPPT PCU,

which we would very much like to try, but I was utterly unable to source

one the last time I tried.

The Ashapower MPPT charger also seems to be competent and trouble-free.

It can cut off mains power to a standalone inverter when solar power is

available for charging, which is quite clever. My only gripe about it is

that its terminals are physically too small for 10mm² cables.

Older systems

We used a heavy beast of a 4kVA MPPT PCU from Bluebird Solar for several

years. When it started having intermittent problems after some years, we

tried to get the company to send someone to take a look at it, but they

ghosted us. When it died after another couple of years, we discovered

that the company had ditched its solar PCU business entirely. Ugh. 👎

Before that, we used a sleek

3kVA wall-mounted MPPT PCU

from

Flin Energy. It worked well at

first, but literally caught fire and blew up one day. Flin promptly

replaced it under warranty, but the new unit would freeze up randomly

and require a hard reboot. Although the company were quite responsive,

they were ultimately unable to debug the problem. Ugh.

Before that, we used a non-MPPT 2kVA/48V SuKam PCU for a while. It

worked, but it just couldn't charge the batteries enough. It came in

handy as a backup while we were waiting for Flin#1 to be replaced, but

it later died at some point when we were using it as a backup again. We

got it fixed in Haldwani, and it's slated for independent non-solar use

in the shed in future.

Our first "real" solar inverter was a 1kVA/24V PCU from a company in

Pune named Enertech, which had excellent pre-sales service, and an utter

lack of post-sales support. We had to send it back for repairs, and they

(a) didn't fix it properly, and (b) sent it back to the wrong address.

Ugh. 👎👎

Our first setup was a strange hybrid. We already had a nice 1kVA

Microtek UPS that we wanted to keep using, but it ran off a very

solar-unfriendly 36V battery bank. We eventually managed to get someone

to fabricate a 36V solar charger locally, and hooked it up to a string

of two 12V 250W solar panels plus another 100W panel to make up the 36V.

That kept us going for three years.

(Eccentric though this little setup was, the inverter is actually still

working at a friend's house ten years later. 👍👍👍)

Solar panels

We've always bought whichever panels were most easily available. Right

now, we have 12×385W

ReneSola panels, connected

in three parallel strings of four panels each, for a total of 4.6kW.

(This layout gives us an array with a maximum open-circuit voltage of

192.4V. The Statcon PCU actually specifies a maximum allowed voltage of

190V, but fortunately this limit can be raised in the configuration

settings. An array of four strings of three panels each would have a

lower maximum voltage, but we didn't want that because the currents would be correspondingly

higher.)

Some years ago, we had installed 6×250W panels with some expectation

that we would double the capacity later. But after just eighteen months,

we could not find matching panels, and much cheaper and better panels

had become common. In our experience, it's best to treat any panels as a

one-shot setup. And when you upgrade the panels, likely as not you will

end up wanting to upgrade the PCU at the same time.

Here's a photograph of our solar panels, propped up on some bricks so

that they slope rougly 20° towards the south. The roof has three levels,

each with one string of panels. Three pairs of wires go into a combiner

box, and one pair goes inside the battery room right at the top. With an

occasional cleaning, this setup works well enough. We don't get (or, at

least, haven't had) winds strong enough to dislodge the panels, but we

do want to mount them properly someday.

(There was a time when MC4 connectors and tools were not available at

any reasonable price, and it was standard practice to cut the connectors

off solar panels and wrap lots of tape around the connections to the

inverter. Happily, that is no longer the case.)

Batteries

Although we spent

three years fighting Exide in consumer court,

we now use… eight Exide SolarBlitz 150Ah (flooded lead acid) batteries.

They are wired up in two parallel banks of four batteries each. Each of

these batteries weighs nearly sixty kilograms, and they need to have

distilled water topped up periodically.

Our battery bank has to work the hardest when we have long mains outages

in poor weather (monsoon or winter rains), where solar charging is

limited or absent. Although our mains supply is not as bad as it used to

be when we first moved here, a days-long outage would surprise us only

a little. Unfortunately, bad weather often coincides with long outages.

The battery room

All of the generation equipment lives in a

small room on the highest level of our roof,

accessible through a trapdoor opening into the upstairs bathroom. Here's

what it looked like while we were in the middle of setting up the latest

systems.

We had our friendly neighbourhood welder make the pieces for the battery

stand, painted them, hauled them up into the battery room, and bolted

them together into the form seen here. The batteries and PCU were hauled

up one by one using a block-and-tackle pulley suspended from a piece of

steel rebar fitted into holes on two walls.

The large white-and-green box on the floor is the Statcon PCU. The small

blue box on top is the Ashapower MPPT charger. Behind those two, the

black box is the Microtek UPS, perched on top of a voltage stabiliser.

In the left corner, you can see a couple of big bottles of distilled

water, and the tail end of the yellow nylon strap and the white nylon

rope that were used to haul things up.

There's also some networking equipment and a Raspberry pi in the battery

room, used to monitor everything else.

Grid-tied generation

We get a lot of "Why don't you just…" questions, the most common of

which is about having an on-grid setup where we can feed power into the

grid. (There was a time when such questions were even framed in a "Why

would you say no to becoming rich?" sort of way.)

It must have been around 2015 when we first heard about the

Uttarakhand Renewable Energy

Development Agency (UREDA) scheme to subsidise small on-grid solar

plants. At the time, they offered a generous subsidy to set up a 5kW

installation. We decided against applying for it for a variety of

reasons, which boiled down to "too much trouble", especially while we

were already busy building a house.

Since the on-grid setup of the time had no local power backup, we could

have installed a separate inverter and batteries for our equipment. But

then again, we would have had to get a large-enough system to withstand

long outages… and we wouldn't have been able to use the solar panels to

charge it. That was probably the single largest factor in our decision,

since power backup was our primary concern.

Yes, we could have found enough land to install 5kW of panels (which

would not have fit on our rooftop, given the panels available at the

time). We could have upgraded to a three-phase connection, but nobody in

the village had one, and we were told that we would have to pay for new

wiring and some transformer uphill to be changed.

Could we have done all that, and then all the paperwork and running

around required to get the "no-objection certificate" from UPCL for the

net-metering connection and then the UREDA subsidy application? It took

us two separate trips to Bhimtal, sixty kilometres away, just to correct

a spelling error in the name on our electricity bill, so… well, we

certainly didn't need the hassle.

(We know people who have actually done all of this and come out of it

with a working on-grid power plant. It certainly wasn't impossible, just

difficult and not compelling enough for us.)

Things are different now, and it's hardly surprising that people from

states like Kerala, where power outages are short and the

state electricity board

makes it simple to setup grid-tied rooftop solar plants, have a much

easier decision to make. Even in Uttarakhand, a lot has changed in the

past ten years.

The mains supply here has improved. Availability is

higher on average, especially in bad weather. UPCL has a helpline to

register complaints, repair times have reduced, and power fluctuations

are usually less severe and a bit less frequent. (It's all relative,

though: just yesterday, our mains voltage was at 160V for several hours…

but at least it wasn't 60V, I guess?)

More significantly, hybrid inverters that have local battery storage

have become common and much cheaper. You can get a net-metering

connection from UPCL and export power to the grid even without applying

for the UREDA subsidy. Our own power requirements are different too. We

still prioritise availability, but at the 5kVA scale, cost savings have

gained in importance.

But are we going to switch to an on-grid setup? Not today.

Heating water

We have two 100-litre evacuated-tube solar water heaters on the roof,

which feed a 25-litre electric water heater inside the house. We could

run this 2kW heater off the inverter, but we don't bother, because the

solar heaters are good enough most of the time.

The solar heaters are visible in the photograph of the roof above.

They're the cylindrical white tanks just above the aluminium ladder. The

white plastic tank at the top right contains cold water that feeds into

one heater, and the output from the first heater feeds into the second

one, and the output from the second heater then feeds the house.

This arrangement of two heaters in series is important. We can use a

little hot water from the second tank at any time of the day, and the

water that flows in to replace it from the other heater will be (at

least) warm. If we had let in cold water instead, the remaining water in

the heater would cool down too quickly to reheat during the day. (Being

able to use the hot water only once a day is a frequent complaint with

single-heater systems.)

We applied successfully to UPCL for its 1₹/litre monthly rebate for

having solar water heaters installed. The rebate was later increased to

75₹/50 litres, but a recent electricity bill says we actually got

335.34₹ off, so I don't know how it's calculated any more.

DC lighting

We've also used a couple of smaller-scale DC solar setups with one panel

and a 12V charge controller, mostly for indoor LED lighting (but also to

power a wifi relay station).

We've had good results with the

Sparkel

12V/20A MPPT charge controller and a small 12Ah LFP (Lithium Ferrophosphate)

battery (n=2) to power a couple of LED tubelights.

We've also used a couple of inexpensive

d.light S3 solar lanterns

for years and years. They aren't very bright, but they last a long time.

Putting them outside in the sun once in a while is all the attention

they need, and they have never given us any trouble. None of the other

lanterns we've tried come close.

Solar dehydration

Despite our best efforts at extracting power and heat from the sun, it

turns out to have a little left over to grow fruits and vegetables on

our farm. To squeeze out every last drop, we also run a

solar

dehydrator from Rudra Solar to dry our produce: lemongrass, thyme,

peppermint leaves, sliced peaches and apricots, pears, grapes (to make

raisins), boiled turmeric, and so on.

The solar panel plugs into the front of the box and runs a little fan

for airflow through vents in the floor and up through the drying trays

inside. The dryer also comes with an AC power adapter. We plug it in (to

the house inverter, of course) to make sure nothing becomes soggy

overnight (peaches and grapes, for example, take many days to dry fully).